ABOUT US

Axis House Group are the front runners when it comes to the development, supply and distribution of specialised formulations of cutting-edge metallurgical processes and products, tailored exclusively for the mining industry on a global scale.

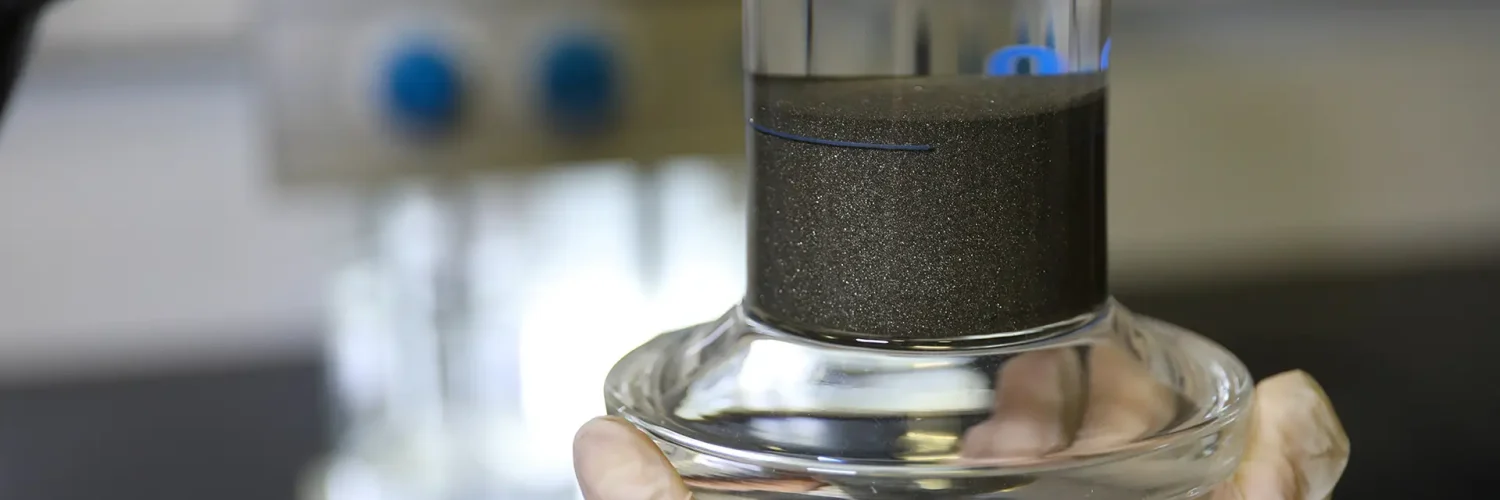

We are driven by our commitment to maximise yield and efficiency and with a fully equipped laboratory, as well as stringent monitoring of global chemical markets. We are able to combine the collective knowledge of our experts in milling, flotation, sedimentation, leaching and analytics with world class equipment to leverage our expertise, fully addressing our client’s needs.

We know that remaining progressively innovative goes far beyond specialised product development and that is why we always strive to create financial value for each and every one of our clients.

OUR PORTFOLIO OF COMPANIES

Our Global Presence

Axis House Group’s commitment to serving its customers globally is reflected in its expanding footprint. With branches spread across various strategic locations worldwide, the company ensures seamless access to its products and services.

LEGACY OF INNOVATION

PIONEERING

Born from the need to produce a technological breakthrough for mining operations, specifically focused on production processes within central Africa, Axis House Group were the pioneers in establishing a necessary distribution model, that was both financially sound and lead-time oriented, enabling substantial changes to be made in how African mining operations approach all facets of the production process.

INNOVATION

Axis House Group has been adapting to the evolving mining landscape for nearly 20 years. We are committed to progressive innovation, constantly reassessing and reinventing ourselves. Our focus remains unwavering on delivering unique, cost-effective solutions through cutting-edge metallurgical processes and products, tailored for global mining markets.

QUALITY

Our strength at Axis House Group is rooted in our heritage of social responsibility, profound understanding of our clients’ needs, technical expertise and a steadfast commitment to quality products and exceptional service. We prioritize excellence in everything we do, ensuring our clients receive nothing less than the best.

EXPERTISE

Our foundation at Axis House Group is built on a heritage of social responsibility, a deep understanding of our clients’ needs, technical expertise, and an unwavering commitment to delivering quality products and exceptional service. We uphold a standard of excellence in all aspects of our operations, ensuring our clients always receive the highest level of satisfaction.

OUR SERVICES

MINERAL PROCESSING SOLUTIONS

Custom Chemical Solutions for Optimal Recovery

Need a Product Brochure? Contact Us!

AXIS HOUSE GROUP

We inherently believe that operational excellence can only be achieved through continuous and progressive innovation.

HYDROFROTH

For all frother related products and queries.

REAGENT SOLUTIONS

For all commodity related products and queries.

JOHANNESBURG

Suite 21, Katherine & West,

3rd Floor, 114 West Street,

Sandown, Sandton

Tel: + 27 11 463 4888

info@axishouse.co.za

CAPE TOWN

The Board Walk,

Cnr Oxford and Victoria Ave,

Hout Bay

Tel: + 27 11 463 4888

info@axishouse.co.za

©2025, Axis House Group

Tsars - Az Orosz Elegancia és Modern Technológia Találkozása

A Tsars kaszinó nemcsak kiváló promócióiról és bőkezű bónuszairól ismert, hanem az egyedi, lenyűgöző játékélményéről is, amely megkülönbözteti a versenytársaitól. A platform sikeresen egyesíti a klasszikus kaszinóhangulatot, amely a cári Oroszország fénykorát idézi, a legmodernebb online funkciókkal és technológiákkal, így ideális választás kezdők és haladó játékosok számára egyaránt. A Tsars látogatói egy vizuálisan lenyűgöző világba csöppenhetnek, ahol az arany, a vörös és a királyi bíbor színek uralják a felületet, miközben a háttérben a legújabb játéktechnológia biztosítja a zökkenőmentes élményt. Ez a platform nem egyszerűen egy online kaszinó, hanem egy átfogó szórakozási élmény, amely minden részletében a minőséget és az elegancia iránt elkötelezett.

A Cári Tematika és Dizájn Filozófia

A Tsars kaszinó névválasztása és vizuális identitása nem véletlen. A platform teljes mértékben az orosz cárok fényűző és pompázatos világát idézi, amely egyszerre sugároz hatalmat, gazdagságot és kifinomultságot. A weboldal dizájnja aprólékosan kidolgozott: a főoldalon trónterem jellegű háttér fogadja a látogatókat, ahol az arany díszítések, a bársony textúrák és az impozáns oszlopok mind a cári palotákat juttatják eszünkbe. Ez a tematika nem csupán esztétikai választás, hanem része annak a márkafilo zófiának, amely a Tsars-t a prémium online kaszinók közé emeli.

A felhasználói felület azonban nem áldozza fel a funkcionalitást a stílus oltárán. A navigáció intuitív és logikus, a menüpontok könnyen elérhetők, és a játékok kategorizálása átgondolt. A keresőfunkció kiváló, lehetővé téve a játékosok számára, hogy gyorsan megtalálják kedvenc címeiket vagy felfedezzenek új játékokat. A színvilág, bár drámai, nem túlzó vagy zavaró, hanem kellemes kontrasztot biztosít a játékok és a szöveges tartalmak számára. Ez a dizájn filozófia bizonyítja, hogy a Tsars csapata megértette: a valódi luxus nem ordít, hanem finoman kommunikál.

Játékportfólió és Szoftverpartnerek

A Tsars kaszinó játékkönyvtára lenyűgözően gazdag, több mint 3000 címmel büszkélkedhet a vezető szoftvergyártóktól. A platform stratégiai partnerségeket épített ki az iparág legnagyobb neveivel, így a játékosok élvezhetik a NetEnt, Microgaming, Play'n GO, Pragmatic Play, Evolution Gaming és még sok más prémium fejlesztő alkotásait. Ez a diverzitás biztosítja, hogy minden típusú játékos megtalálja a számára tökéletes szórakozást, legyen szó klasszikus slotokról, modern videó nyerőgépekről, asztali játékokról vagy élő kaszinó élményekről.

- Nyerőgépek óriási választéka: A Tsars több mint 2500 slotot kínál, a klasszikus gyümölcsös gépektől a legújabb megajackpot címekig. Megtalálhatók a legendás játékok, mint a Gonzo's Quest, Starburst, Book of Dead, valamint az újdonságok is folyamatosan bővítik a kínálatot.

- Jackpot játékok: A progresszív jackpot rajongói sem csalódnak, hiszen a platform kínálja a Mega Moolah, Mega Fortune és más multi-milliós nyereménylehetőséggel kecsegtető címeket, ahol a szerencse bármikor mosolyoghat a játékosra.

- Asztali játékok sokszínűsége: A rulett, blackjack, baccarat és póker számtalan változata elérhető, beleértve az európai, amerikai és francia verziókat, valamint egzotikus változatokat is, mint a Lightning Roulette vagy a Blackjack Party.

- Élő kaszinó prémium szinten: Az Evolution Gaming által működtetett élő kaszinó szekció HD minőségű streameket, professzionális krupiékat és interaktív játékélményt biztosít 24/7, több tucat asztallal és változatos tétlimitekkel.

Bónuszok és VIP Program

A Tsars kaszinó bónuszprogramja igazán királyi bánásmódot biztosít a játékosok számára. Az üdvözlő csomag különösen bőkezű, amely általában több szakaszból áll, összesített értéke pedig elérheti a több százezer forintot is egyenértékben. Az új játékosok az első befizetésük után jelentős bónuszt kapnak, amely gyakran 100%-os vagy még magasabb, valamint ingyenes pörgetéseket népszerű slot játékokra. A további befizetések is jutalmazottak progresszív bónuszokkal, amelyek fokozatosan építik a játékosok egyenlegét.

Ami igazán kitűnővé teszi a Tsars bónuszrendszerét, az az átláthatóság és a játékosbarát feltételek. A wagering követelmények versenyképesek, általában 35-40x között mozognak, ami ésszerű az iparági standardokhoz képest. A bónuszok felhasználhatók széles körű játékokon, és a feltételek világosan kommunikáltak a felhasználási szabályzatban. Nincs rejtett meglepetés vagy apró betűs csapda, amely gyakran jellemzi a kevésbé megbízható kaszinók ajánlatait.

- Heti promóciók: A Tsars minden héten új promóciókat indít, amelyek tartalmazhatnak reload bónuszokat, cashback ajánlatokat, ingyenes pörgetéseket vagy speciális versenyeket hatalmas nyereményalapokkal.

- Személyre szabott ajánlatok: A rendszer megtanulja a játékosok preferenciáit, és ennek megfelelően személyre szabott bónuszokat ajánl, amelyek relevánsak az adott játékos számára.

- VIP Lojalitási Program: A Tsars többszintes VIP programja kiemelkedő jutalmakat biztosít a hűséges játékosoknak. A szintek között előrelépve a játékosok magasabb cashback százalékokat, gyorsabb kifizetéseket, személyes account managereket és exkluzív meghívásokat kapnak különleges eseményekre.

- Születésnapi bónuszok: A Tsars nem felejti el játékosai születésnapját, és különleges meglepetésekkel, exkluzív bónuszokkal ünnepli velük együtt a nagy napot.

- Turnékok és versenyek: Rendszeres slot versenyek és turnékek várják a versenyképes játékosokat, ahol nemcsak a szerencse, hanem az ügyesség is számít, és a díjazás bőkezű.

Felhasználói Élmény és Technológia

A Tsars kaszinó technológiai infrastruktúrája élvonalbeli, amely biztosítja a zökkenőmentes játékélményt minden platformon. A weboldal gyors betöltési időkkel rendelkezik, a játékok villámgyorsan indulnak, és a szerverteljesítmény stabilan magas. A platform HTML5 technológián alapul, ami azt jelenti, hogy böngészőfüggetlen és nem igényel Flash plugint, így biztonságosabb és modernebb megoldást kínál.

A mobiloptimalizáció kiváló: a Tsars tökéletesen működik okostelefonokon és táblagépeken egyaránt, iOS és Android rendszereken. A mobilweboldal reszponzív dizájnja automatikusan alkalmazkodik a képernyő méretéhez, így ugyanaz a prémium élmény elérhető útközben is, mint otthon a számítógép előtt. A játékok nagy része elérhető mobilon, és a teljes funkcionalitás - beleértve a befizetéseket, kifizetéseket és ügyfélszolgálatot - egy gombnyomásra elérhető. Nincs szükség app letöltésére, ami egyszerűsíti a használatot és helyet takarít meg az eszközön.

Biztonság, Licenc és Ügyfélszolgálat

A Tsars kaszinó komolyan veszi a biztonságot és a szabályozási megfelelést. A platform nemzetközileg elismert játékhatóság által kiadott licenccel rendelkezik, amely garantálja a fair play-t és a játékosok jogainak védelmét. Az SSL titkosítás minden adatátvitelt véd, így a személyes és pénzügyi információk biztonságban vannak. A kaszinó betartja a GDPR előírásokat, és átlátható adatvédelmi szabályzattal rendelkezik.

Az ügyfélszolgálat a Tsars egyik erőssége. A támogatás 24/7 elérhető élő chat, e-mail és telefonos formában is. A csapat többnyelvű, beleértve a magyar nyelvet is, így a játékosok anyanyelvükön kommunikálhatnak problémáik megoldása érdekében. A munkatársak gyorsan reagálnak, szakértőek, és valóban segítőkészek, nem csupán sablonválaszokat adnak. A legtöbb kérdés perceken belül megoldódik az élő chaten keresztül, míg a komplexebb ügyek is maximum 24 órán belül rendeződnek e-mail útján.

- Proaktív segítség: Az ügyfélszolgálat gyakran proaktívan keresi meg a játékosokat, ha technikai problémákat észlel, nem várva, hogy a játékos panaszkodjon.

- Részletes útmutatók: A Tsars átfogó súgó szekciót és videó tutoriálokat kínál a gyakori kérdésekről, így sok probléma önállóan megoldható.

- Közösségi média jelenlét: A kaszinó aktív a közösségi médiában, ahol további támogatást és gyors válaszokat biztosít a játékosoknak.

- Felelős játék eszközök: A Tsars különböző eszközöket biztosít a felelős játékhoz, beleértve a befizetési limiteket, vesztességi limiteket, időzítőket és önkizárási lehetőségeket.

Összefoglalva, a Tsars kaszinó egy komplett szórakozási csomag, amely egyesíti a vizuális pompát, a technológiai kiválóságot és a játékosközpontú szolgáltatásokat. Az orosz cári tematika egyedi hangulatot teremt, miközben a modern funkciók biztosítják a kényelmes és biztonságos játékélményt. A gazdag játékválaszték, a bőkezű bónuszok, a kiváló ügyfélszolgálat és a megbízható működés mind hozzájárulnak ahhoz, hogy a Tsars a legjobb online kaszinók között foglaljon helyet a magyar játékosok számára. Akár kezdő, akár tapasztalt játékos, a Tsars királyi élménnyel szolgál minden látogatójának.

Tsars - Az Orosz Elegancia és Modern Technológia Találkozása

A Tsars kaszinó nemcsak kiváló promócióiról és bőkezű bónuszairól ismert, hanem az egyedi, lenyűgöző játékélményéről is, amely megkülönbözteti a versenytársaitól. A platform sikeresen egyesíti a klasszikus kaszinóhangulatot, amely a cári Oroszország fénykorát idézi, a legmodernebb online funkciókkal és technológiákkal, így ideális választás kezdők és haladó játékosok számára egyaránt. A Tsars látogatói egy vizuálisan lenyűgöző világba csöppenhetnek, ahol az arany, a vörös és a királyi bíbor színek uralják a felületet, miközben a háttérben a legújabb játéktechnológia biztosítja a zökkenőmentes élményt. Ez a platform nem egyszerűen egy online kaszinó, hanem egy átfogó szórakozási élmény, amely minden részletében a minőséget és az elegancia iránt elkötelezett.

A Cári Tematika és Dizájn Filozófia

A Tsars kaszinó névválasztása és vizuális identitása nem véletlen. A platform teljes mértékben az orosz cárok fényűző és pompázatos világát idézi, amely egyszerre sugároz hatalmat, gazdagságot és kifinomultságot. A weboldal dizájnja aprólékosan kidolgozott: a főoldalon trónterem jellegű háttér fogadja a látogatókat, ahol az arany díszítések, a bársony textúrák és az impozáns oszlopok mind a cári palotákat juttatják eszünkbe. Ez a tematika nem csupán esztétikai választás, hanem része annak a márkafilo zófiának, amely a Tsars-t a prémium online kaszinók közé emeli.

A felhasználói felület azonban nem áldozza fel a funkcionalitást a stílus oltárán. A navigáció intuitív és logikus, a menüpontok könnyen elérhetők, és a játékok kategorizálása átgondolt. A keresőfunkció kiváló, lehetővé téve a játékosok számára, hogy gyorsan megtalálják kedvenc címeiket vagy felfedezzenek új játékokat. A színvilág, bár drámai, nem túlzó vagy zavaró, hanem kellemes kontrasztot biztosít a játékok és a szöveges tartalmak számára. Ez a dizájn filozófia bizonyítja, hogy a Tsars csapata megértette: a valódi luxus nem ordít, hanem finoman kommunikál.

Játékportfólió és Szoftverpartnerek

A Tsars kaszinó játékkönyvtára lenyűgözően gazdag, több mint 3000 címmel büszkélkedhet a vezető szoftvergyártóktól. A platform stratégiai partnerségeket épített ki az iparág legnagyobb neveivel, így a játékosok élvezhetik a NetEnt, Microgaming, Play'n GO, Pragmatic Play, Evolution Gaming és még sok más prémium fejlesztő alkotásait. Ez a diverzitás biztosítja, hogy minden típusú játékos megtalálja a számára tökéletes szórakozást, legyen szó klasszikus slotokról, modern videó nyerőgépekről, asztali játékokról vagy élő kaszinó élményekről.

- Nyerőgépek óriási választéka: A Tsars több mint 2500 slotot kínál, a klasszikus gyümölcsös gépektől a legújabb megajackpot címekig. Megtalálhatók a legendás játékok, mint a Gonzo's Quest, Starburst, Book of Dead, valamint az újdonságok is folyamatosan bővítik a kínálatot.

- Jackpot játékok: A progresszív jackpot rajongói sem csalódnak, hiszen a platform kínálja a Mega Moolah, Mega Fortune és más multi-milliós nyereménylehetőséggel kecsegtető címeket, ahol a szerencse bármikor mosolyoghat a játékosra.

- Asztali játékok sokszínűsége: A rulett, blackjack, baccarat és póker számtalan változata elérhető, beleértve az európai, amerikai és francia verziókat, valamint egzotikus változatokat is, mint a Lightning Roulette vagy a Blackjack Party.

- Élő kaszinó prémium szinten: Az Evolution Gaming által működtetett élő kaszinó szekció HD minőségű streameket, professzionális krupiékat és interaktív játékélményt biztosít 24/7, több tucat asztallal és változatos tétlimitekkel.

Bónuszok és VIP Program

A Tsars kaszinó bónuszprogramja igazán királyi bánásmódot biztosít a játékosok számára. Az üdvözlő csomag különösen bőkezű, amely általában több szakaszból áll, összesített értéke pedig elérheti a több százezer forintot is egyenértékben. Az új játékosok az első befizetésük után jelentős bónuszt kapnak, amely gyakran 100%-os vagy még magasabb, valamint ingyenes pörgetéseket népszerű slot játékokra. A további befizetések is jutalmazottak progresszív bónuszokkal, amelyek fokozatosan építik a játékosok egyenlegét.

Ami igazán kitűnővé teszi a Tsars bónuszrendszerét, az az átláthatóság és a játékosbarát feltételek. A wagering követelmények versenyképesek, általában 35-40x között mozognak, ami ésszerű az iparági standardokhoz képest. A bónuszok felhasználhatók széles körű játékokon, és a feltételek világosan kommunikáltak a felhasználási szabályzatban. Nincs rejtett meglepetés vagy apró betűs csapda, amely gyakran jellemzi a kevésbé megbízható kaszinók ajánlatait.

- Heti promóciók: A Tsars minden héten új promóciókat indít, amelyek tartalmazhatnak reload bónuszokat, cashback ajánlatokat, ingyenes pörgetéseket vagy speciális versenyeket hatalmas nyereményalapokkal.

- Személyre szabott ajánlatok: A rendszer megtanulja a játékosok preferenciáit, és ennek megfelelően személyre szabott bónuszokat ajánl, amelyek relevánsak az adott játékos számára.

- VIP Lojalitási Program: A Tsars többszintes VIP programja kiemelkedő jutalmakat biztosít a hűséges játékosoknak. A szintek között előrelépve a játékosok magasabb cashback százalékokat, gyorsabb kifizetéseket, személyes account managereket és exkluzív meghívásokat kapnak különleges eseményekre.

- Születésnapi bónuszok: A Tsars nem felejti el játékosai születésnapját, és különleges meglepetésekkel, exkluzív bónuszokkal ünnepli velük együtt a nagy napot.

- Turnékok és versenyek: Rendszeres slot versenyek és turnékek várják a versenyképes játékosokat, ahol nemcsak a szerencse, hanem az ügyesség is számít, és a díjazás bőkezű.

Felhasználói Élmény és Technológia

A Tsars kaszinó technológiai infrastruktúrája élvonalbeli, amely biztosítja a zökkenőmentes játékélményt minden platformon. A weboldal gyors betöltési időkkel rendelkezik, a játékok villámgyorsan indulnak, és a szerverteljesítmény stabilan magas. A platform HTML5 technológián alapul, ami azt jelenti, hogy böngészőfüggetlen és nem igényel Flash plugint, így biztonságosabb és modernebb megoldást kínál.

A mobiloptimalizáció kiváló: a Tsars tökéletesen működik okostelefonokon és táblagépeken egyaránt, iOS és Android rendszereken. A mobilweboldal reszponzív dizájnja automatikusan alkalmazkodik a képernyő méretéhez, így ugyanaz a prémium élmény elérhető útközben is, mint otthon a számítógép előtt. A játékok nagy része elérhető mobilon, és a teljes funkcionalitás - beleértve a befizetéseket, kifizetéseket és ügyfélszolgálatot - egy gombnyomásra elérhető. Nincs szükség app letöltésére, ami egyszerűsíti a használatot és helyet takarít meg az eszközön.

Biztonság, Licenc és Ügyfélszolgálat

A Tsars kaszinó komolyan veszi a biztonságot és a szabályozási megfelelést. A platform nemzetközileg elismert játékhatóság által kiadott licenccel rendelkezik, amely garantálja a fair play-t és a játékosok jogainak védelmét. Az SSL titkosítás minden adatátvitelt véd, így a személyes és pénzügyi információk biztonságban vannak. A kaszinó betartja a GDPR előírásokat, és átlátható adatvédelmi szabályzattal rendelkezik.

Az ügyfélszolgálat a Tsars egyik erőssége. A támogatás 24/7 elérhető élő chat, e-mail és telefonos formában is. A csapat többnyelvű, beleértve a magyar nyelvet is, így a játékosok anyanyelvükön kommunikálhatnak problémáik megoldása érdekében. A munkatársak gyorsan reagálnak, szakértőek, és valóban segítőkészek, nem csupán sablonválaszokat adnak. A legtöbb kérdés perceken belül megoldódik az élő chaten keresztül, míg a komplexebb ügyek is maximum 24 órán belül rendeződnek e-mail útján.

- Proaktív segítség: Az ügyfélszolgálat gyakran proaktívan keresi meg a játékosokat, ha technikai problémákat észlel, nem várva, hogy a játékos panaszkodjon.

- Részletes útmutatók: A Tsars átfogó súgó szekciót és videó tutoriálokat kínál a gyakori kérdésekről, így sok probléma önállóan megoldható.

- Közösségi média jelenlét: A kaszinó aktív a közösségi médiában, ahol további támogatást és gyors válaszokat biztosít a játékosoknak.

- Felelős játék eszközök: A Tsars különböző eszközöket biztosít a felelős játékhoz, beleértve a befizetési limiteket, vesztességi limiteket, időzítőket és önkizárási lehetőségeket.

Összefoglalva, a Tsars kaszinó egy komplett szórakozási csomag, amely egyesíti a vizuális pompát, a technológiai kiválóságot és a játékosközpontú szolgáltatásokat. Az orosz cári tematika egyedi hangulatot teremt, miközben a modern funkciók biztosítják a kényelmes és biztonságos játékélményt. A gazdag játékválaszték, a bőkezű bónuszok, a kiváló ügyfélszolgálat és a megbízható működés mind hozzájárulnak ahhoz, hogy a Tsars a legjobb online kaszinók között foglaljon helyet a magyar játékosok számára. Akár kezdő, akár tapasztalt játékos, a Tsars királyi élménnyel szolgál minden látogatójának.

Corsaza Online Casino - Innováció és Játékosbarát Megoldások

A Corsaza online casino az innováció és a játékosbarát megoldások tökéletes ötvözete, amely az online szerencsejáték új generációját képviseli. Az oldal kiválóan működik mobileszközökön is, biztosítva a zökkenőmentes játékélményt bárhol és bármikor, gyors kifizetéseket kínál, amelyek versenyképesek a piac legjobbjainak ajánlataival, és rendszeres promóciókkal motiválja a visszatérő játékosokat, hogy folyamatosan élvezzék a platform előnyeit. A Corsaza nem csupán egy újabb online kaszinó a sok közül, hanem egy jövőorientált platform, amely megérti a 21. századi játékosok igényeit: mobilitást, sebességet, átláthatóságot és kiváló értéket. Ez a kaszinó bebizonyítja, hogy egy új szereplő is képes magas színvonalat nyújtani, ha a megfelelő stratégiával és elkötelezettséggel dolgozik.

Mobil-Elsőbbségű Dizájn és Felhasználói Élmény

A Corsaza online casino fejlesztése során a mobil élmény került a középpontba, tükrözve azt a valóságot, hogy ma már a legtöbb játékos okostelefonon vagy tableten keresztül éri el kedvenc kaszinóját. A platform reszponzív webdizájnja automatikusan alkalmazkodik bármilyen képernyőmérethez, így ugyanaz a prémium élmény elérhető egy 6,7 colos okostelefonon, mint egy 12,9 colos iPad Pro-n vagy egy 27 colos monitoron. Ez a "mobil-first" filozófia nem csupán technikai megoldás, hanem a Corsaza elkötelezettségének jele a modern játékosok felé.

A mobil felület gyors, reagálókész és intuitív. A menüpontok könnyen elérhetők hüvelykujjal történő navigációval, a játékok gyorsan töltődnek be, és a teljes funkcionalitás - beleértve a regisztrációt, befizetést, kifizetést és ügyfélszolgálati kapcsolatot - problémamentesen működik mobilon. A Corsaza nem készített külön mobilalkalmazást, ami valójában előny: nincs szükség letöltésre vagy tárhely felhasználásra, a játékosok egyszerűen megnyitják a weboldalt böngészőjükben, és már játszhatnak is. A PWA (Progressive Web App) technológia lehetővé teszi, hogy a felhasználók "telepítsék" az oldalt a kezdőképernyőjükre, így app-szerű élményt kapnak anélkül, hogy ténylegesen alkalmazást kellene letölteniük.

Gyors Kifizetések - A Corsaza Versenyelőnye

A Corsaza online casino egyik legnagyobb vonzereje a rendkívül gyors kifizetési sebesség, amely a platform elkötelezettsége a játékosok elégedettsége iránt. Míg sok kaszinó napokat vagy akár heteket is halogat a kifizetésekkel, a Corsaza törekszik arra, hogy minden tranzakciót a lehető leggyorsabban feldolgozzon. Ez nemcsak technikai kérdés, hanem filozófiai megközelítés: a játékosok pénze az ő pénzük, és azonnal hozzá kell férniük, amikor csak akarnak.

Az e-pénztárcás kifizetések (Skrill, Neteller, ecoPayz) általában 24 órán belül, sok esetben akár néhány órán belül feldolgozásra kerülnek. A kriptovaluták még gyorsabbak lehetnek, gyakran 1-2 órán belül megérkezik a Bitcoin vagy Ethereum átutalás. A bankkártyás kifizetések, amelyek általában lassabbak az iparágban, a Corsazánál is 2-4 munkanapot vesznek igénybe, de ez is gyorsabb, mint sok versenytársnál. A banki átutalások, bár továbbra is a leglassabb opció, általában 3-5 munkanapon belül teljesülnek.

- Minimális függőben lévő idő: A Corsaza minimalizálja a "pending" időszakot, amely alatt a kifizetési kérelmek feldolgozás alatt állnak. Ez gyakran csak néhány óra, ellentétben más kaszinókkal, ahol ez napokig eltarthat.

- Gyors KYC folyamat: Az első kifizetés előtti személyazonosság ellenőrzés automatizált és gyors. A legtöbb esetben a feltöltött dokumentumok néhány órán belül jóváhagyásra kerülnek, nem napok alatt.

- Magas kifizetési limitek: A Corsaza versenyképes napi és havi kifizetési limiteket kínál, ami azt jelenti, hogy a nagyobb nyerők is gyorsan hozzájuthatnak pénzükhöz anélkül, hogy több részletben kellene kifizetéseket kérniük.

- VIP gyorsított kifizetés: A VIP játékosok kiemelt elbánásban részesülnek, beleértve a prioritásos kifizetési feldolgozást, amely még tovább csökkenti a várakozási időt.

- Hétvégi feldolgozás: Ellentétben sok kaszinóval, amely csak hétköznapokon dolgozza fel a kifizetéseket, a Corsaza hétvégén is aktív, így a játékosok nem veszítenek el 2-3 napot csak azért, mert pénteken kérték a kifizetést.

Folyamatos Promóciók és Játékos-Megtartás

A Corsaza online casino megértette, hogy az üdvözlő bónusz önmagában nem elég a játékosok hosszú távú megtartásához. Ezért a platform kiemelt figyelmet fordít a rendszeres promóciókra, amelyek folyamatosan motiválják a játékosokat a visszatérésre. A hét minden napja más-más ajánlatot hoz: hétfőn reload bónuszt, kedden ingyenes pörgetéseket, szerdán cashbacket, és így tovább. Ez a változatosság biztosítja, hogy mindig legyen valami új és izgalmas, amire a játékosok várhatnak.

A Corsaza promóciós naptára átlátható és előre közzétett, így a játékosok előre tervezhetik befizetéseiket, hogy maximalizálják a bónuszok értékét. A platform nem csak a nagy összegeket befizetőket jutalmazza, hanem az alkalmi játékosokat is, alacsony minimális befizetési követelményekkel a promóciók aktiválásához. Ez a demokratikus megközelítés biztosítja, hogy mindenki érezhesse magát értékesnek, függetlenül a játékvolumentől.

- Naponta változó ajánlatok: Minden nap új promóció várja a játékosokat, így mindig van ok a visszatérésre és érdemes rendszeresen ellenőrizni a promóciós oldalt.

- Tematikus kampányok: Ünnepek és különleges alkalmak körül a Corsaza tematikus kampányokat indít extra bónuszokkal, versenyekkel és különleges jutalmakkal.

- Személyre szabott ajánlatok: A platform algoritmusa elemzi a játékosok szokásait, és ennek megfelelően személyre szabott bónuszokat ajánl, amelyek valóban relevá nsak az adott játékos számára.

- Exkluzív VIP események: A VIP játékosok meghívást kapnak exkluzív promóciókra, privát turnékre és különleges eseményekre, ahol a díjazás még bőkezűbb.

Közösségépítés és Ügyfélkapcsolatok

A Corsaza online casino nem csupán tranzakciós platformként működik, ahol a játékosok befizetnek, játszanak és kivesznek, hanem törekszik egy élő közösség megteremtésére. A platform aktív a közösségi médiában, ahol rendszeresen oszt meg játék tippeket, stratégiákat, nyertes történeteket és promóciós bejelentéseket. A Facebook, Instagram és Twitter jelenlét lehetővé teszi a játékosok számára, hogy kapcsolatba lépjenek a kaszinóval és egymással is, megosztva tapasztalataikat és tippjeiket.

Az ügyfélszolgálat a Corsaza másik erőssége. A 24/7 elérhető támogatási csapat gyors, barátságos és hatékony. Az élő chat funkció lehetővé teszi az azonnali kommunikációt, ahol a legtöbb kérdés perceken belül megválaszolásra kerül. A magyar nyelvű támogatás kiemelt fontosságú a magyar játékosok számára, és a Corsaza biztosítja, hogy anyanyelvű munkatársak álljanak rendelkezésre. Az e-mail támogatás is gyors, általában 24 órán belül érkező részletes válaszokkal, amelyek nem csupán sablonszövegek, hanem valódi, személyre szabott segítséget nyújtanak.

Játékválaszték Folyamatos Bővítése

A Corsaza online casino játékkönyvtára dinamikusan fejlődik. Bár a platform viszonylag fiatal, már most is több mint 1500 játékot kínál, és ez a szám hetente nő új címek hozzáadásával. A kaszinó szoros kapcsolatban áll a vezető játékfejlesztőkkel, így az újdonságok gyakran napokkal megjelenésük után már elérhetők a Corsaza játékosai számára. Ez a gyorsaság biztosítja, hogy a platform mindig naprakész és izgalmas maradjon.

A játékválasztás kurátori megközelítést követ: a Corsaza csapata gondosan választja ki, mely játékokat adja hozzá a könyvtárhoz. Nem minden új játék kerül fel automatikusan, csak azok, amelyek valóban minőséget képviselnek és hozzáadott értéket nyújtanak a játékosoknak. Ez a szelektív hozzáállás biztosítja, hogy a könyvtár ne legyen túlzsúfolt alacsony minőségű címekkel, amelyek elvonják a figyelmet az igazán jó játékoktól. A platform rendszeresen gyűjt visszajelzéseket a játékosoktól arról, mely játékokat szeretnének látni, és figyelembe veszi ezeket a kéréseket a jövőbeli bővítések során.

- Népszerűségi rangsor: A Corsaza megmutatja, mely játékok a legnépszerűbbek a játékosok körében, segítve ezzel a döntéshozatalt azok számára, akik új címeket keresnek.

- Új játékok külön szekciója: Az újdonságok saját kategóriát kapnak, így a játékosok könnyen felfedezhetik a legfrissebb kiadásokat.

- Demó módok: Szinte minden játék kipróbálható demó módban valódi pénz kockáztatása nélkül, ami tökéletes a játékok megismeréséhez.

- Szűrési lehetőségek: Fejlett szűrők és keresési funkciók segítenek a játékosoknak gyorsan megtalálni a keresett típusú játékokat (volatilitás, szolgáltató, téma, funkciók szerint).

- Játék ajánló rendszer: Az AI-alapú ajánló rendszer megtanulja a játékos preferenciáit, és új játékokat javasol, amelyek valószínűleg tetszeni fognak neki.

Jövőbeli Tervek és Fejlesztések

A Corsaza online casino nem nyugszik a babérjain, folyamatosan dolgozik új funkciók és fejlesztések bevezetésén. A platform jövőképe ambiciózus: a következő hónapokban és években számos újdonság várható, amelyek tovább emelik a játékélményt. A gamifikáció mélyebb integrálása, küldetések és teljesítmények rendszere, amely extra jutalmakat ad a különböző mérföldkövek eléréséért. A virtuális valóság (VR) integráció is a távlati tervek között szerepel, amely teljesen új dimenziót nyitna az online kaszinózásban.

A Corsaza elkötelezett a felelős játék további erősítése iránt is, tervezik a mesterséges intelligencia alapú figyelmeztető rendszer bevezetését, amely felismeri a problémás játékszokások korai jeleit, és proaktívan segítséget ajánl a játékosoknak. Az adatbiztonság területén is folyamatos fejlesztések várhatók, beleértve a biometrikus hitelesítés opcióját, amely még biztonságosabbá teszi a fiókokat.

Összességében a Corsaza online casino egy dinamikusan fejlődő, innovatív platform, amely a játékosok igényeit helyezi mindenek elé. A kiváló mobil élmény, a gyors kifizetések, a rendszeres promóciók, a folyamatosan bővülő játékválaszték és a kiváló ügyfélszolgálat mind hozzájárulnak ahhoz, hogy ez a fiatal kaszinó gyorsan népszerűvé váljon a magyar játékosok körében. Azok, akik modern, megbízható és játékosbarát online kaszinót keresnek, bizton választhatják a Corsaza online casinot, amely bebizonyította, hogy egy új szereplő is képes magas színvonalat nyújtani és komoly versenyt támasztani a régóta piacon lévő nagyoknak. A jövő ígéretes, és a Corsaza biztosan fontos szerepet fog játszani a magyar online szerencsejáték piac formálásában.

Corsaza Online Casino - Innováció és Játékosbarát Megoldások

A Corsaza online casino az innováció és a játékosbarát megoldások tökéletes ötvözete, amely az online szerencsejáték új generációját képviseli. Az oldal kiválóan működik mobileszközökön is, biztosítva a zökkenőmentes játékélményt bárhol és bármikor, gyors kifizetéseket kínál, amelyek versenyképesek a piac legjobbjainak ajánlataival, és rendszeres promóciókkal motiválja a visszatérő játékosokat, hogy folyamatosan élvezzék a platform előnyeit. A Corsaza nem csupán egy újabb online kaszinó a sok közül, hanem egy jövőorientált platform, amely megérti a 21. századi játékosok igényeit: mobilitást, sebességet, átláthatóságot és kiváló értéket. Ez a kaszinó bebizonyítja, hogy egy új szereplő is képes magas színvonalat nyújtani, ha a megfelelő stratégiával és elkötelezettséggel dolgozik.

Mobil-Elsőbbségű Dizájn és Felhasználói Élmény

A Corsaza online casino fejlesztése során a mobil élmény került a középpontba, tükrözve azt a valóságot, hogy ma már a legtöbb játékos okostelefonon vagy tableten keresztül éri el kedvenc kaszinóját. A platform reszponzív webdizájnja automatikusan alkalmazkodik bármilyen képernyőmérethez, így ugyanaz a prémium élmény elérhető egy 6,7 colos okostelefonon, mint egy 12,9 colos iPad Pro-n vagy egy 27 colos monitoron. Ez a "mobil-first" filozófia nem csupán technikai megoldás, hanem a Corsaza elkötelezettségének jele a modern játékosok felé.

A mobil felület gyors, reagálókész és intuitív. A menüpontok könnyen elérhetők hüvelykujjal történő navigációval, a játékok gyorsan töltődnek be, és a teljes funkcionalitás - beleértve a regisztrációt, befizetést, kifizetést és ügyfélszolgálati kapcsolatot - problémamentesen működik mobilon. A Corsaza nem készített külön mobilalkalmazást, ami valójában előny: nincs szükség letöltésre vagy tárhely felhasználásra, a játékosok egyszerűen megnyitják a weboldalt böngészőjükben, és már játszhatnak is. A PWA (Progressive Web App) technológia lehetővé teszi, hogy a felhasználók "telepítsék" az oldalt a kezdőképernyőjükre, így app-szerű élményt kapnak anélkül, hogy ténylegesen alkalmazást kellene letölteniük.

Gyors Kifizetések - A Corsaza Versenyelőnye

A Corsaza online casino egyik legnagyobb vonzereje a rendkívül gyors kifizetési sebesség, amely a platform elkötelezettsége a játékosok elégedettsége iránt. Míg sok kaszinó napokat vagy akár heteket is halogat a kifizetésekkel, a Corsaza törekszik arra, hogy minden tranzakciót a lehető leggyorsabban feldolgozzon. Ez nemcsak technikai kérdés, hanem filozófiai megközelítés: a játékosok pénze az ő pénzük, és azonnal hozzá kell férniük, amikor csak akarnak.

Az e-pénztárcás kifizetések (Skrill, Neteller, ecoPayz) általában 24 órán belül, sok esetben akár néhány órán belül feldolgozásra kerülnek. A kriptovaluták még gyorsabbak lehetnek, gyakran 1-2 órán belül megérkezik a Bitcoin vagy Ethereum átutalás. A bankkártyás kifizetések, amelyek általában lassabbak az iparágban, a Corsazánál is 2-4 munkanapot vesznek igénybe, de ez is gyorsabb, mint sok versenytársnál. A banki átutalások, bár továbbra is a leglassabb opció, általában 3-5 munkanapon belül teljesülnek.

- Minimális függőben lévő idő: A Corsaza minimalizálja a "pending" időszakot, amely alatt a kifizetési kérelmek feldolgozás alatt állnak. Ez gyakran csak néhány óra, ellentétben más kaszinókkal, ahol ez napokig eltarthat.

- Gyors KYC folyamat: Az első kifizetés előtti személyazonosság ellenőrzés automatizált és gyors. A legtöbb esetben a feltöltött dokumentumok néhány órán belül jóváhagyásra kerülnek, nem napok alatt.

- Magas kifizetési limitek: A Corsaza versenyképes napi és havi kifizetési limiteket kínál, ami azt jelenti, hogy a nagyobb nyerők is gyorsan hozzájuthatnak pénzükhöz anélkül, hogy több részletben kellene kifizetéseket kérniük.

- VIP gyorsított kifizetés: A VIP játékosok kiemelt elbánásban részesülnek, beleértve a prioritásos kifizetési feldolgozást, amely még tovább csökkenti a várakozási időt.

- Hétvégi feldolgozás: Ellentétben sok kaszinóval, amely csak hétköznapokon dolgozza fel a kifizetéseket, a Corsaza hétvégén is aktív, így a játékosok nem veszítenek el 2-3 napot csak azért, mert pénteken kérték a kifizetést.

Folyamatos Promóciók és Játékos-Megtartás

A Corsaza online casino megértette, hogy az üdvözlő bónusz önmagában nem elég a játékosok hosszú távú megtartásához. Ezért a platform kiemelt figyelmet fordít a rendszeres promóciókra, amelyek folyamatosan motiválják a játékosokat a visszatérésre. A hét minden napja más-más ajánlatot hoz: hétfőn reload bónuszt, kedden ingyenes pörgetéseket, szerdán cashbacket, és így tovább. Ez a változatosság biztosítja, hogy mindig legyen valami új és izgalmas, amire a játékosok várhatnak.

A Corsaza promóciós naptára átlátható és előre közzétett, így a játékosok előre tervezhetik befizetéseiket, hogy maximalizálják a bónuszok értékét. A platform nem csak a nagy összegeket befizetőket jutalmazza, hanem az alkalmi játékosokat is, alacsony minimális befizetési követelményekkel a promóciók aktiválásához. Ez a demokratikus megközelítés biztosítja, hogy mindenki érezhesse magát értékesnek, függetlenül a játékvolumentől.

- Naponta változó ajánlatok: Minden nap új promóció várja a játékosokat, így mindig van ok a visszatérésre és érdemes rendszeresen ellenőrizni a promóciós oldalt.

- Tematikus kampányok: Ünnepek és különleges alkalmak körül a Corsaza tematikus kampányokat indít extra bónuszokkal, versenyekkel és különleges jutalmakkal.

- Személyre szabott ajánlatok: A platform algoritmusa elemzi a játékosok szokásait, és ennek megfelelően személyre szabott bónuszokat ajánl, amelyek valóban relevá nsak az adott játékos számára.

- Exkluzív VIP események: A VIP játékosok meghívást kapnak exkluzív promóciókra, privát turnékre és különleges eseményekre, ahol a díjazás még bőkezűbb.

Közösségépítés és Ügyfélkapcsolatok

A Corsaza online casino nem csupán tranzakciós platformként működik, ahol a játékosok befizetnek, játszanak és kivesznek, hanem törekszik egy élő közösség megteremtésére. A platform aktív a közösségi médiában, ahol rendszeresen oszt meg játék tippeket, stratégiákat, nyertes történeteket és promóciós bejelentéseket. A Facebook, Instagram és Twitter jelenlét lehetővé teszi a játékosok számára, hogy kapcsolatba lépjenek a kaszinóval és egymással is, megosztva tapasztalataikat és tippjeiket.

Az ügyfélszolgálat a Corsaza másik erőssége. A 24/7 elérhető támogatási csapat gyors, barátságos és hatékony. Az élő chat funkció lehetővé teszi az azonnali kommunikációt, ahol a legtöbb kérdés perceken belül megválaszolásra kerül. A magyar nyelvű támogatás kiemelt fontosságú a magyar játékosok számára, és a Corsaza biztosítja, hogy anyanyelvű munkatársak álljanak rendelkezésre. Az e-mail támogatás is gyors, általában 24 órán belül érkező részletes válaszokkal, amelyek nem csupán sablonszövegek, hanem valódi, személyre szabott segítséget nyújtanak.

Játékválaszték Folyamatos Bővítése

A Corsaza online casino játékkönyvtára dinamikusan fejlődik. Bár a platform viszonylag fiatal, már most is több mint 1500 játékot kínál, és ez a szám hetente nő új címek hozzáadásával. A kaszinó szoros kapcsolatban áll a vezető játékfejlesztőkkel, így az újdonságok gyakran napokkal megjelenésük után már elérhetők a Corsaza játékosai számára. Ez a gyorsaság biztosítja, hogy a platform mindig naprakész és izgalmas maradjon.

A játékválasztás kurátori megközelítést követ: a Corsaza csapata gondosan választja ki, mely játékokat adja hozzá a könyvtárhoz. Nem minden új játék kerül fel automatikusan, csak azok, amelyek valóban minőséget képviselnek és hozzáadott értéket nyújtanak a játékosoknak. Ez a szelektív hozzáállás biztosítja, hogy a könyvtár ne legyen túlzsúfolt alacsony minőségű címekkel, amelyek elvonják a figyelmet az igazán jó játékoktól. A platform rendszeresen gyűjt visszajelzéseket a játékosoktól arról, mely játékokat szeretnének látni, és figyelembe veszi ezeket a kéréseket a jövőbeli bővítések során.

- Népszerűségi rangsor: A Corsaza megmutatja, mely játékok a legnépszerűbbek a játékosok körében, segítve ezzel a döntéshozatalt azok számára, akik új címeket keresnek.

- Új játékok külön szekciója: Az újdonságok saját kategóriát kapnak, így a játékosok könnyen felfedezhetik a legfrissebb kiadásokat.

- Demó módok: Szinte minden játék kipróbálható demó módban valódi pénz kockáztatása nélkül, ami tökéletes a játékok megismeréséhez.

- Szűrési lehetőségek: Fejlett szűrők és keresési funkciók segítenek a játékosoknak gyorsan megtalálni a keresett típusú játékokat (volatilitás, szolgáltató, téma, funkciók szerint).

- Játék ajánló rendszer: Az AI-alapú ajánló rendszer megtanulja a játékos preferenciáit, és új játékokat javasol, amelyek valószínűleg tetszeni fognak neki.

Jövőbeli Tervek és Fejlesztések

A Corsaza online casino nem nyugszik a babérjain, folyamatosan dolgozik új funkciók és fejlesztések bevezetésén. A platform jövőképe ambiciózus: a következő hónapokban és években számos újdonság várható, amelyek tovább emelik a játékélményt. A gamifikáció mélyebb integrálása, küldetések és teljesítmények rendszere, amely extra jutalmakat ad a különböző mérföldkövek eléréséért. A virtuális valóság (VR) integráció is a távlati tervek között szerepel, amely teljesen új dimenziót nyitna az online kaszinózásban.

A Corsaza elkötelezett a felelős játék további erősítése iránt is, tervezik a mesterséges intelligencia alapú figyelmeztető rendszer bevezetését, amely felismeri a problémás játékszokások korai jeleit, és proaktívan segítséget ajánl a játékosoknak. Az adatbiztonság területén is folyamatos fejlesztések várhatók, beleértve a biometrikus hitelesítés opcióját, amely még biztonságosabbá teszi a fiókokat.

Összességében a Corsaza online casino egy dinamikusan fejlődő, innovatív platform, amely a játékosok igényeit helyezi mindenek elé. A kiváló mobil élmény, a gyors kifizetések, a rendszeres promóciók, a folyamatosan bővülő játékválaszték és a kiváló ügyfélszolgálat mind hozzájárulnak ahhoz, hogy ez a fiatal kaszinó gyorsan népszerűvé váljon a magyar játékosok körében. Azok, akik modern, megbízható és játékosbarát online kaszinót keresnek, bizton választhatják a Corsaza online casinot, amely bebizonyította, hogy egy új szereplő is képes magas színvonalat nyújtani és komoly versenyt támasztani a régóta piacon lévő nagyoknak. A jövő ígéretes, és a Corsaza biztosan fontos szerepet fog játszani a magyar online szerencsejáték piac formálásában.